Product, Tooling Design & Engineering Support

UP Mold assesses your drawings and provides engineering guidance to help you design mould-able parts that are optimized for manufacture. From tool design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing high-quality injection moulded parts.

Product Design Assistance

Our suggestion on this steps to design the product features, specs and industrial design follow. Upmold is certainly in a position to help you develop your new projects or re-design current products and implement these steps on behalf of clients by meeting in person and teleconferencing with you and your sales & marketing and technical people each step of the way. some information should refer to Plastic Injection Molding Part Design Guidelines.

Product Development

Mold Design Support

Engineer Software

Design For Manufacturability (DFM)

DFM is a helpful tool that Upmold provides its customers to help minimize tooling costs and to help expedite the manufacturing process; this is a key step, we should analyze carefully following our checking list that Upmold’s DFM includes below processes, please watch video to learn more details or read the DFM Sample

Basic Information

- Cavities

- Using Material

- Shrinkage

- Part size & weight analysis

- Mold steels

- Moldbase steel and spec

- Injection machine size

Mold structure

- Sink mark analysis

- Draft analysis

- Engraving and Aspect spec

- parting line analysis

- Insert line analysis

- Slide and retractor lines

- Ejector line

- Gate location and size

- Layout

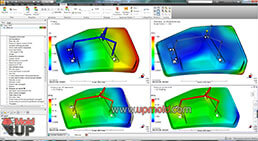

Mold Flow Analysis For Mold & Tooling Design

The Moldflow analysis is a helpful simulation for mould design concept evaluated and optimized the design options, that guarantees us to build a high-quality plastic injection mold successfully. Through this simulation, we can find out the best gate location, cycle time simulation analysis, cooling checking, sink marks preventing, welding line improving, venting designing and injection parameter primary analysis that is indispensable to us. (Watch Moldflow Analysis Report Sample)

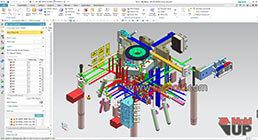

Tooling & Mold Design

Upmold uses the lasted engineer software to build the 2D or 3D mold structure and simulate that it is right and capable; our designer should follow the ultimate confirmed DFM report to build mold structure, and assemble mold components that are the customer’s mold standard.

Generally, We use these engineer softwares to build a model as below:

- Pro-Engineer for product design model.

- Unigraphics NX for3D mold design model.

- Auto CAD for 2D mold design.

- Moldflow for Moldflow analysis and optimized simulation.

Product Design & Development Assist

Our product development and design team has over 10 years of combined product development experience and has been exposed to many different applications and industries. Through many years of experience, we have developed a workflow that ensures a smooth and well-developed process plan for new projects.

Product Design Process

Product Development Process

We Accepted File Formats

We accepted some file formats as below, that should be convenient for communication, please provide these acceptable formats to us.